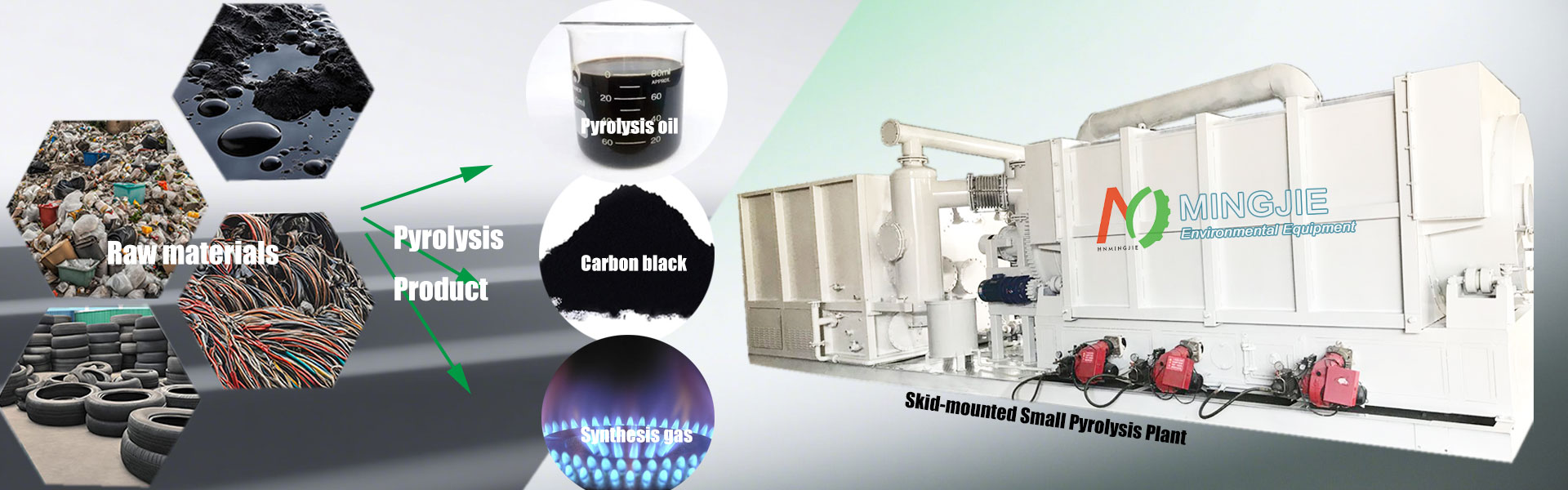

The small pyrolysis plant adopts skid-mounted operation mode, with a processing capacity of 1-2T/D. It can be used to process municipal solid waste(MSW), medical waste, plastics, tires, sludge, etc. Solid waste is decomposed into oil, gas, carbon black and combustible gas through pyrolysis reaction.

Small Pyrolysis Plant for Sale

- Skid-mounted design: The pyrolysis reactor, condensation separation, tail gas treatment, and control system are integrated in a standard container.

- Compact and flexible: The small pyrolysis machine has a small footprint and is suitable for small-scale pyrolysis. It can process 1-2 tons of waste tires a day.

- Quick installation: After the small pyrolysis machine is transported to the site, it only needs simple installation and commissioning. This shortens the construction period (from several months to 1-2 weeks).

If you are interested in purchasing or learning more about Small Pyrolysis Plant, you can contact Mingjie Group. Let me know if you need help finding specific models!

| Model | MJ-2 |

| Capacity | 1-2T/D |

| Reactor Size | D1400mm*L4000mm |

| Rector Thickness | 16mm/18mm |

| Land Required | L30*W15*H7m |

| Application | Whole Tyres,Waste Plastic, Oil Sludge, Municipal Solid Waste, Medicine Waste, Aluminum Paper, Waste Cables |

| Initial heating fuel | Natural glas/Diesel/LPG/Wood/Pyrolysis Oil |

| Heating Method | Direct Heating |

| Condenser | Circulating Water Cooling |

| Operation | Batch Type |

Small Pyrolysis Unit for Green Recycling Project

Small Pyrolysis Machine Application

Small pyrolysis machines can process a variety of solid wastes, such as waste plastics, tires, medical waste, sludge, etc. It converts solids into fuel oil, carbon black and synthesis gas through pyrolysis technology.

Pyrolysis integrates temperature sensors, flow controllers and catalytic cracking devices to achieve precise control of the pyrolysis process. Small pyrolysis plants adopt explosion-proof design and flue gas purification system, in order to ensure that waste gas emissions meet standards.

Core Structure of Skid-mounted Small Pyrolysis Machine

The skid-mounted mobile pyrolysis unit adopts a full-process integrated design. It integrates the feeding system, pyrolysis reactor, heating device, gas purification unit and product recovery system into a standardized framework. The skid-mounted small scale pyrolysis unit is highly integrated and flexible, providing an efficient and low-cost solution for distributed waste treatment.

The skid-mounted small pyrolysis plant is 90% pre-assembled before leaving the factory. It only takes 1-2 containers for transportation. The waste pyrolysis project site only needs to connect to water and electricity, which significantly shortens the construction period.

As a new environmental protection technology, small pyrolysis unit can achieve waste reduction, harmlessness and resource utilization through high temperature and anaerobic decomposition. Pyrolysis plant provides an innovative path for municipal solid waste management.

Plastics and tires are high-molecular wastes in modern society. Traditional landfilling will occupy land, and incineration will produce dioxins. Small-scale pyrolysis technology can achieve efficient resource conversion through precise temperature control and catalytic system.

Small-scale pyrolysis plants transform environmental liability into industrial assets by “molecular reconstruction” of plastics and tires. This pyrolysis technology has spawned a closed-loop economic model of “waste → raw materials → products → renewable resources”.