In 2021, Mingjie Group completed the shipment and installation of MJ-2 small pyrolysis machine for sale to Peru. The mini pyrolysis plant can process 2 tons of waste tires per day. It can also process waste plastics, municipal solid waste, medical waste, oil sludge, etc.

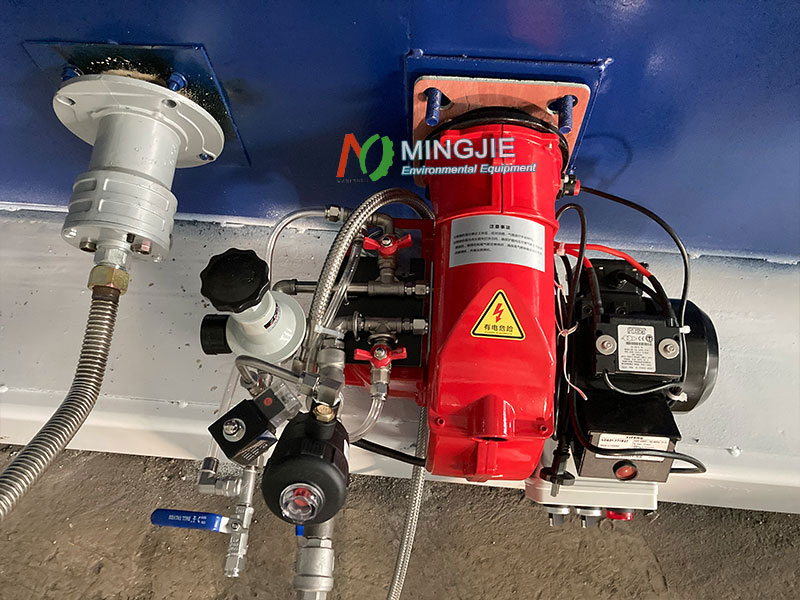

The production and assembly of the skid-mounted pyrolysis equipment are all completed in Mingjie Factory. After the equipment arrives on site, customers only need to place it in a fixed position. The small pyrolysis machine can start working after connecting to external electrical appliances.

The MJ-2 mini pyrolysis plant can convert waste tires into fuel oil, carbon black, steel wire, and combustible gas. It achieves resource recovery and environmental pollution reduction, and has gradually become an effective solution for waste tire treatment.

Waste Tire Pyrolysis Project in Peru

The Peruvian tire market has a strong demand. As the number of cars increases, the amount of waste tires generated will also increase accordingly. Waste tires provide sufficient raw materials for pyrolysis recycling projects.

The Peruvian government vigorously promotes the development of renewable energy. The fuel oil and combustible gas produced by the pyrolysis of waste tires can be used as part of renewable energy. The waste tire pyrolysis project is in line with Peru’s energy development strategy and is expected to enjoy relevant tax incentives.

Globally, the pyrolysis of waste tires is on the rise. According to statistics, the annual output of pyrolysis oil and carbon black converted from waste tires through pyrolysis technology has reached 1.7 million tons and 1.2 million tons respectively. This achievement is due to the effective utilization of 4.5 million tons of waste tires.

Small Pyrolysis Machine for Sale

The professional pyrolysis plant provided by Mingjie Group can achieve efficient and pollution-free waste tire processing. The small pyrolysis machine adopts batch operation mode, which can feed the whole tire without crushing.

We also provide comprehensive technical support and distillation equipment for pyrolysis oil from waste tires. They can convert waste tires into pyrolysis oil, and pyrolysis oil into diesel or gasoline.

Skid-mounted small pyrolysis machines and distillation equipment have the advantage of strong mobility. They are easy to transport and install, and can be quickly transferred to different locations according to needs.

The small pyrolysis machine adopts a modular design, and each functional module is independent and closely connected. It is convenient for the commissioning, maintenance and upgrading of the equipment. Although small, it has all the necessary functions, such as pyrolysis reactor, heating system, condensation system, exhaust gas treatment system, etc.

Conclusion

The pyrolysis plant is the core processing equipment of the waste tire recycling project. It can carry out centralized pyrolysis treatment of waste tires to achieve resource recycling. The skid-mounted small tire pyrolysis equipment can be processed on site, so as to reduce transportation costs and environmental pollution. The mini pyrolysis equipment is suitable for remote areas with imperfect infrastructure or temporary waste tire treatment projects.