For small-scale waste tire pyrolysis projects, Mingjie batch pyrolysis plant can meet the needs. It has small investment and high efficiency. The batch pyrolysis reactor can accommodate whole tires without the need for a crusher.

The batch pyrolysis plant operates in coordination with multiple equipment, such as pyrolysis reactor, condensation and oil-gas separation equipment, and gas purification equipment. Ultimately, it can achieve efficient pyrolysis and resource utilization of waste tires to form final products, such as fuel oil, carbon black, and steel wire.

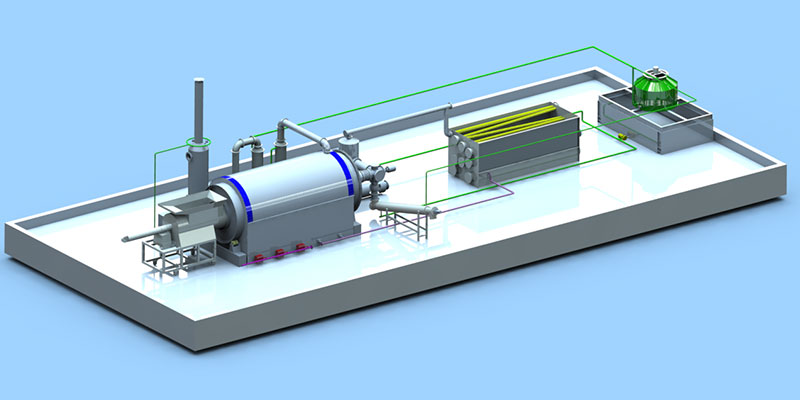

For large-scale waste tire pyrolysis projects, Mingjie Group recommends the use of continuous pyrolysis equipment. It is equipped with an automatic feeding system and can work continuously. The continuous pyrolysis plant adopts a closed design, which can better purify the exhaust gas to meet the emission standards. The fully automatic pyrolysis plant has high processing efficiency and excellent environmental performance.

For a fully automatic pyrolysis plant, a pre-treatment system for waste tire is essential. The pre-processing equipment for waste tires pyrolysis includes wire drawing machine, tire shredder and rubber granulator. Their function is to cut the tire blocks into 5-8mm rubber particles and remove all steel. The fully automatic continuous pyrolysis plant is controlled by PLC and can operate continuously for 24 hours, with a single unit daily processing capacity of 15-50 tons.

Machines Needed for Waste Tire Pyrolysis

Pyrolysis Machine

The pyrolysis reactor is the core equipment of the waste tire pyrolysis system, including a rotary kiln or a fixed bed reactor. It decomposes materials under oxygen-free conditions at high temperatures (300-700°C).

The heating system uses electric heating, gas or fuel oil heating. The combustible gas produced by pyrolysis is used for heating, which can realize energy self-circulation.

Condensation and Oil-gas Separation Equipment

The condensation system uses a water-cooled/air-cooled condenser to cool the high-temperature oil and gas into liquid fuel oil.

The oil-gas separation device can separate liquid oil from synthetic gas (such as methane and hydrogen). The gas can be recycled for the heating system.

Gas Purification Equipment

The dust removal device can remove particulate matter and harmful gases (such as sulfur dioxide) from the exhaust gas.

Conclusions

The above is a brief overview of the key components commonly found in tire pyrolysis systems. However, it is worth noting that the specific waste tire pyrolysis equipment may vary depending on the scale and technology of the tire pyrolysis project.

Please feel free to contact Mingjie Group and share your requirements with us. Our project managers can provide a good solution for tire pyrolysis plant configuration and provide equipment at a favorable price.