In 2020, Mingjie Group completed the installation of batch pyrolysis plant for sale to Ecuador. Ecuadorian customers purchased pyrolysis equipment to process waste plastics. The batch pyrolysis plant is equipped with a dewaxing device, which can effectively avoid the pipe blockage problem in the process of waste plastic treatment.

The working principle of batch pyrolysis equipment is that waste plastics are heated in an oxygen-free or oxygen-deficient environment to break chemical bonds, thereby decomposing into synthesis gas, pyrolysis oil and carbon black. The batch operation of the equipment is that during the pyrolysis process, the addition of raw materials, the pyrolysis reaction and the discharge of products are completed in batches.

Batch Pyrolysis Plant for Sale

We have different types of batch pyrolysis plants for different scales of waste pyrolysis projects. Their processing capacity ranges from 6 to 15T/D, suitable for small-scale or medium-scale production.

Mingjie batch pyrolysis plant for sale has broad application prospects in the field of waste treatment due to its operational flexibility, product quality advantages, maintenance convenience and low investment cost.

The batch pyrolysis plant for sale adopts a large furnace door design, which does not require high material dimensions. It can directly process packaged plastics without the need for pretreatment devices.

Batch Pyrolysis Plant Structure Composition

Pyrolysis Reactor

The pyrolysis reactor is the core component of batch pyrolysis plant for sale, and the reactor is responsible for the occurrence of the pyrolysis reaction. It is usually made of high-temperature resistant and corrosion-resistant metal materials with good thermal insulation performance. In this way, heat loss is reduced and the pyrolysis reaction is carried out in a stable temperature environment.

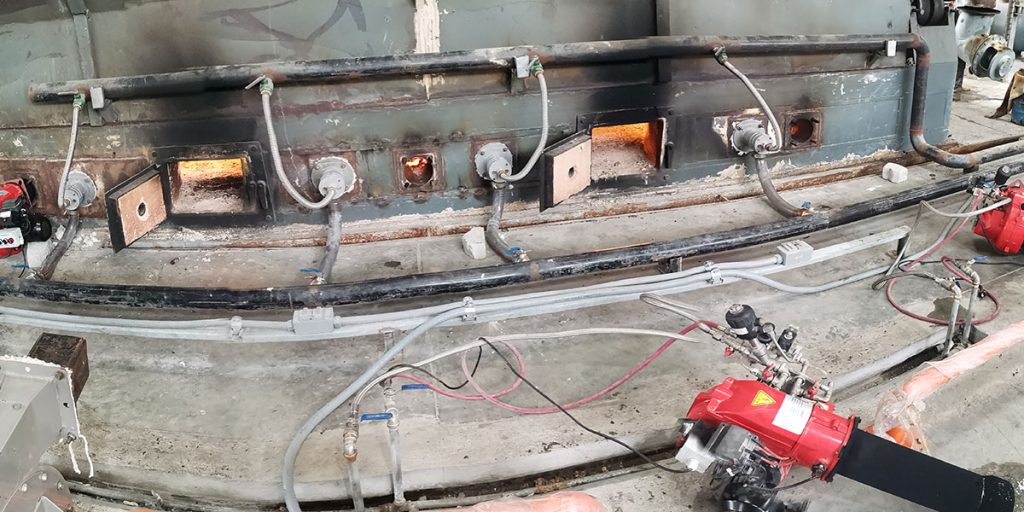

Heating System

The heating system provides the required heat for the pyrolysis reaction. Common heating methods include electric heating, gas heating, and fuel heating. Gas heating and fuel heating are relatively low in cost and fast in heating speed, and are suitable for large-scale pyrolysis production.

Condensation System

The mixed gas produced by pyrolysis passes through the condensation system, and the gaseous tar and water vapor in it are cooled and condensed into liquid. The condensation system is generally composed of a condenser, a cooling medium circulation device, etc., and the cooling medium can be water or air.

Gas Purification System

In addition to combustible gases, the gas discharged from the pyrolysis reactor also contains impurities, such as tar, dust, and sulfide. The gas purification system removes these impurities through various means, such as spraying, adsorption, and filtration. Ensure that the discharged gas meets environmental protection standards while improving the quality of combustible gases.

Control System

Real-time monitoring and control of temperature, pressure, flow and other parameters of the pyrolysis equipment are achieved to ensure safe and stable operation of the equipment. Modern control systems usually use automated control technology. Operators can remotely set and adjust pyrolysis process parameters through the human-machine interface. The system also has fault alarm and automatic protection functions.