In 2020, Mingjie Group completed the installation of the oil sludge pyrolysis unit and waste oil distillation equipment for sale to Suqian, Jiangsu, China. The oil sludge pyrolysis plant is mainly composed of raw material pretreatment system, feeding system, pyrolysis reactor, heating system, cooling system, tail gas purification system, dust removal system and discharging system.

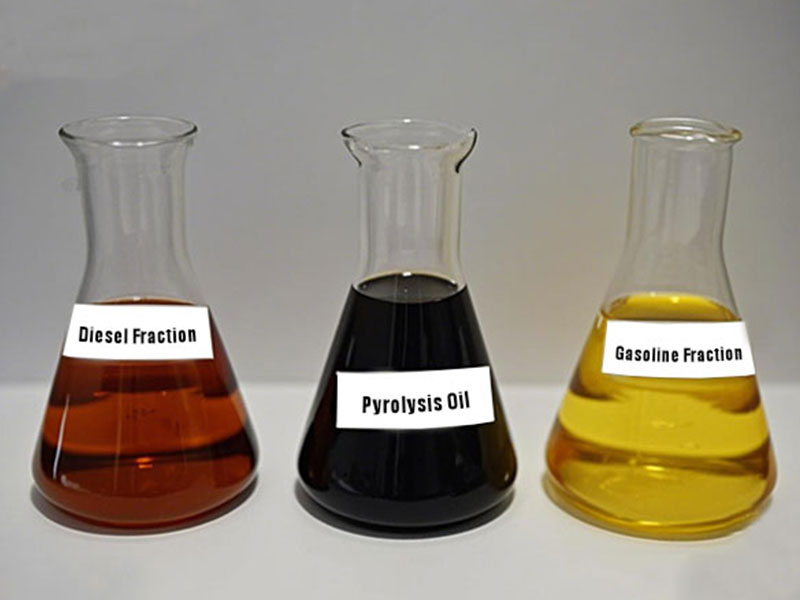

Pyrolysis technology can not only effectively solve the problem of oily sludge treatment, but also realize the resource utilization of waste. Oil sludge can efficiently decompose organic matter in the process of thermal desorption, and the decomposition rate is usually above 80%. The decomposed organic matter can be used to produce fuel oil, gasoline, diesel and other chemicals.

Oil Sludge Pyrolysis Unit Supplier

Mingjie Group is committed to providing comprehensive solid waste recycling solutions, turning solid waste into renewable energy. We customize pyrolysis equipment for customers, which can be used for waste tires, plastics, oil sludge pyrolysis and biomass carbonization.

Oil sludge pyrolysis unit is an environmentally friendly equipment that can achieve waste reduction and resource utilization. Mingjie oil sludge pyrolysis unit has cooperated with customers and has successful projects in many regions. If you also want to build a sludge pyrolysis equipment project, please feel free to contact us inquiry@mingjiegroup.com.

Waste Oil Sludge Pyrolysis Recycling Project

The pyrolysis plant can decompose the heavy oil in the sludge into liquid fuel, solid carbon black and synthetic combustible gas under oxygen-free high temperature conditions. It has the advantages of high degree of automation, safety, efficiency, economy and environmental protection.

Waste oil distillation equipment can convert black pyrolysis oil into gasoline and diesel. Pump the pre-treated waste oil into the reactor and heat it to the working temperature. After the pyrolysis oil is distilled and refined, the required gasoline and diesel are obtained. After the waste oil in the reactor reacts completely, stop heating. Clean the residue at the bottom of the reactor and it can be used again.