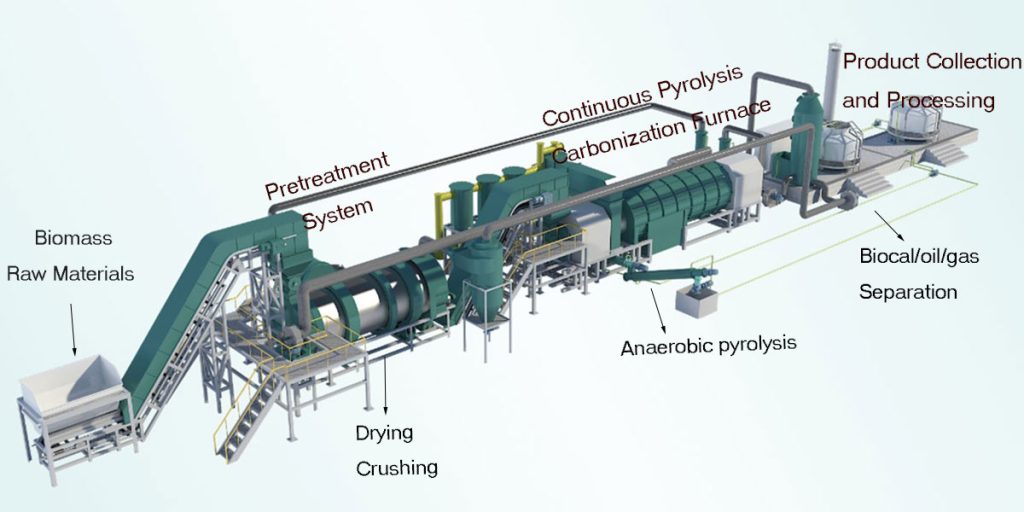

In 2023, Mingjie Group completed the shipment and installation of MJT-2000 wood chips biomass pyrolysis equipment for Sale to Tanzania. The MJT-2000 biomass carbonization plant can process 2 tons of wood chips per hour. It can play a role in different biomass pyrolysis carbonization application scenarios, and provide an effective way to solve the treatment problems of various types of biomass waste.

The biomass pyrolysis carbonization plant is equipped with a high-precision temperature control system, which can ensure that the biomass is pyrolyzed and carbonized under the best reaction conditions. This ensures the stability and consistency of the quality of the biochar product.

Different biomass raw materials and different product requirements can be met by flexibly adjusting the temperature control program, which provides a strong guarantee for the production of high-quality pyrolysis products.

The double-barrel pyrolysis reactor design ensures the smooth operation of pyrolysis and carbonization of biomass raw materials. It ensures the stability of the internal temperature through external heating.

During the pyrolysis process, the generation of harmful substances such as tar can be reduced through reasonable design and process control. For the unavoidable pollutants, the equipment is also equipped with a complete purification and treatment system.

For example, the biomass pyrolysis gas is initially purified through a purification tower to remove tar, acids and other components. Then it is deeply condensed through atomization and heat absorption to further purify the pyrolysis gas.

Biomass Pyrolysis Equipment Application

With the continuous advancement of technology, biomass pyrolysis carbonization equipment will develop in the direction of high efficiency, energy saving and environmental protection.

Biomass pyrolysis carbonization equipment has strong adaptability to raw materials. The processing materials of the equipment include crop straw, branches, reeds, rice husks, livestock and poultry manure, wood industry scraps, waste wood boards, etc.

The biomass pyrolysis equipment application in the production of chemical products (biochar, syngas) is gradually increasing, realizing the high added value of biomass resources.

The application field of biomass pyrolysis carbonization equipment will continue to expand. For example, it uses a variety of biomass raw materials such as poultry and livestock manure to realize the resource utilization of waste. This will drive the growth of demand in the biomass pyrolysis carbonization equipment market.

Biomass Pyrolysis Carbonization Equipment for Sale

Mingjie Group has a variety models of biomass carbonization plant for sale, and the processing capacity of continuous biomass carbonization equipment ranges from 300kg/h to 5T/H.

Raw Material Requirements for Continuous Biomass Pyrolysis Equipment

Before entering the biochar making machine, the raw wood chips must meet certain feeding requirements. Its moisture content should be less than 15%, and the particle size should be uniform small pieces less than 20 mm. In order to ensure the continuous pyrolysis process of biomass, we also provide dryers and pulverizers.

Summary

Today, the world is actively promoting sustainable development and vigorously exploring green energy and environmental protection solutions. Biomass pyrolysis carbonization equipment is like a bright new star, bringing unprecedented opportunities and changes to many industries. For more information or quotes on biomass carbonization plants, please feel free to contact us inquiry@mingjiegroup.com.