In August 2022, Mingjie Group completed the shipment and installation of the MJZ-6 waste oil distillation plant and pyrolysis equipment for sale to Iraq. The customer needs to process a large amount of waste tires. MJ-10 has a waste tire processing capacity of 10T/D, and MJZ-6 has a pyrolysis oil processing capacity of 6T/D.

Waste oil distillation plants are suitable for the distillation and purification of tire pyrolysis oil, thereby increasing the market use of pyrolysis oil. The distillation process produces high-quality fuel oil (diesel or gasoline) in a high vacuum environment.

Our tire pyrolysis plant and distillation equipment is used in tire pyrolysis recycling projects in many countries, such as Canada, Brazil, Peru, Japan, Egypt, Romania, South Africa, etc. They can achieve the goals of waste tire reduction and harmlessness.

Waste Tire Pyrolysis Recycling Project

About 3 billion scrap tires are produced worldwide each year, of which 10-15% are pyrolyzed.

Iraq lacks a formal recycling system, and a large number of tires are piled up or burned, causing soil and air pollution. The import volume of tires is high, and the amount of scrap tires will continue to increase in the future.

As an innovative way to deal with waste tires, the tire pyrolysis recycling project has significant economic, environmental and social benefits.

Carbon black from pyrolysis products is an important industrial raw material with stable market demand and considerable price. Primary carbon black sells for about $1,500/ton, compared to only $100-200/ton from conventional rubber pelletizing.

Clean steel produced by pyrolysis can be sold at the price of ordinary scrap steel. Steel recycled by rubber crushing has a lower profit margin due to residual impurities such as rubber.

In addition, pyrolysis projects have a faster return on investment and can bring higher income to enterprises, making them an attractive investment option.

Pyrolysis Plant Cost

| Type | Bacth Prolysis Plant | Continuous Prolysis Plant |

| Processing Capacity | 1-15T/D | 15-40T/D |

| Energy Consumption | High (need to be cooled and restarted) | Low (continuous operation) |

| Automation | Manual operation | Many Fully automated |

| Investment cost | Low ($100-300K) | High (500K-2M) |

Waste Oil Distillation Plant for Sale

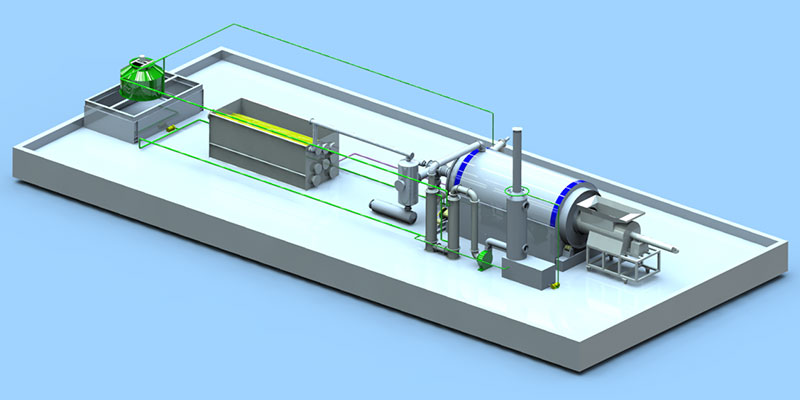

The waste oil distillation plant can purify low-value pyrolysis oil into high-value-added diesel and gasoline, increasing profit margins by 30-50%. The key equipment consists of preheating system, distillation tower, condensation system and vacuum system.

Technical Principle of Distillation Equipment

The waste tire pyrolysis oil distillation equipment adopts high vacuum decompression distillation technology and negative pressure process. It relies on the difference in the mean free path of molecular motion of different substances to achieve liquid-liquid separation. Negative pressure distillation technology not only speeds up the molecular overflow time, but also improves the oil yield.

When the oil is heated, the light and heavy molecules will overflow the liquid surface and enter the gas phase. Due to the different free paths of light and heavy molecules, the distances moved by molecules of different substances are also different, thereby achieving the purpose of material separation.

The pyrolysis oil of waste tires contains sulfides, which will cause serious harm to the environment and human health. Therefore, we set up a pre-treatment desulfurization tower to desulfurize the pyrolysis oil.

If you are interested in tire pyrolysis plant and waste oil distillation plant, or want to know more information, please send email to us inquiry@mingjiegroup.com. We will provide you with detailed answers and professional services.

Summary

Waste oil distillation plant plays an important role in waste pyrolysis recycling projects. Tyre pyrolysis equipment can convert waste tires into renewable energy and reduce dependence on fossil energy. At the same time, distillation equipment can effectively remove sulfides in cracking and reduce harm to the environment.