Medical waste pyrolysis plant is able to decompose medical waste under high temperature, low-oxygen conditions. Compared with incineration, medical waste pyrolysis produces less dioxins and harmful gases. High temperature can effectively kill pathogens and reduce secondary pollution.

The pyrolysis system converts the organic matter in medical waste into pyrolysis oil, carbon black and synthetic gas. The combustible gas and pyrolysis oil produced can be recycled to improve resource efficiency.

Mingjie pyrolysis plant has helped customers deal with medical waste. There are some cases of pyrolysis medical waste equipment application.

The medical waste pyrolysis equipment can transform medical waste into new energy. Medical waste needs to be microwaved before treatment, and the oil yield is 30-50%. The pyrolysis system treats medical waste through high temperature anaerobic decomposition technology. The pyrolysis plant can achieve the harmlessness, reduction and resource utilization of medical waste.

Contact Us To Get Medical Waste Pyrolysis Solution

As a professional pyrolysis plant manufacturer, Mingjie Group can provide effective solutions to reduce environmental pollution and recover resources.

Advantages of Medical Waste Pyrolysis

- Harmless treatment: high temperature (500-800℃) destroys pathogens (such as bacteria and viruses), with an inactivation rate of >99.99%.

- Effective treatment: volume reduction of 70-90%, and the residue is carbon black or ash.

- Resource recovery: can produce synthesis gas or liquid fuel oil.

- Low emission: closed system avoids dioxin generation, and tail gas is purified and discharged in compliance with standards.

- Strong adaptability: can treat mixed medical waste.

Medical Waste Pyrolysis Plant for Sale

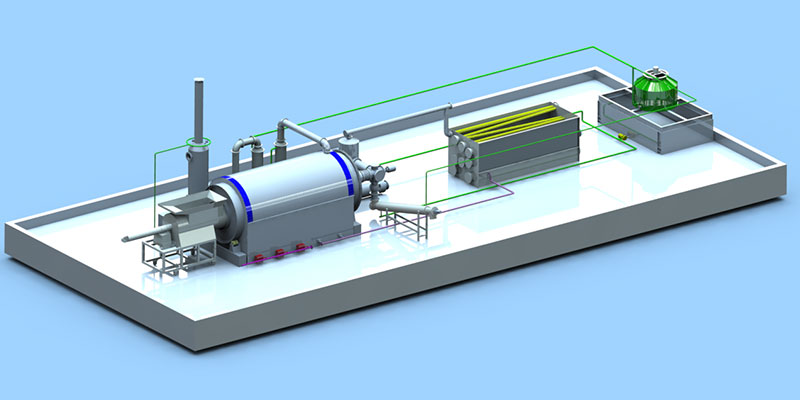

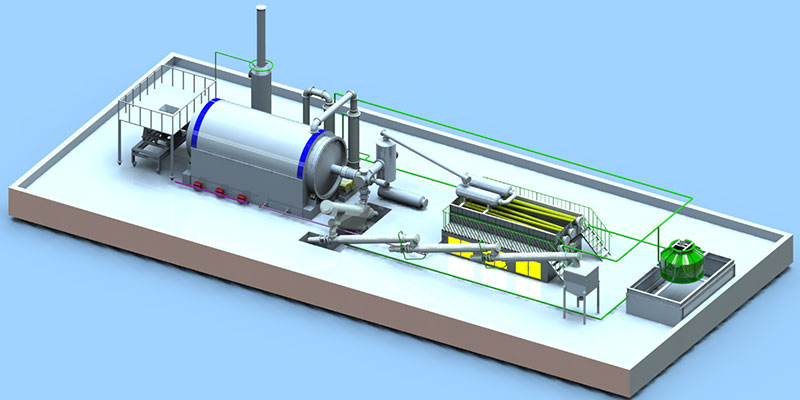

Mingjie pyrolysis plants are divided into Small Pyrolysis Plant, Batch Pyrolysis Plan, Semi-continuous Pyrolysis Plant and Continuous Pyrolysis Plant according to different operating methods and capacities.

Small Pyrolysis Plant

- Skid-mounted design: The pyrolysis reactor, feeding system, condensation separation, tail gas treatment, and control system are integrated in a standard container.

- Compact and flexible: The small pyrolysis machine has a small footprint and is suitable for small-scale pyrolysis. It can process 1-2T/D waste tires.

- Quick installation: After the small pyrolysis machine is transported to the site, it only needs simple installation and commissioning.

Warning: Undefined array key "hotspot_offset_x" in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Trying to access array offset on value of type null in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Undefined array key "hotspot_offset_x" in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Trying to access array offset on value of type null in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Batch Pyrolysis Plan

- Can be loaded with whole tyres or packed plastic bale, without shredding.

- Capacity of 6-15T/D, which is suitable for small-scale or medium-scale production.

- Low investment cost and high slag discharge efficiency.

- Equipped with dewaxing device to effectively avoid pipe clogging problems during plastic processing.

Semi Continuous Pyrolysis Plant

- Feeding size shall be 5-8mm rubber granule, tyre shall be shredded and steel wire will be removed.

- Processong capacity 15-16T/D tyre, 12T/D plastic.

- Equipped with auto feeder system, feeding can be done at high temperature.

- From feeding to discharging, the whole press is sealed, operation environment is clean.

Warning: Undefined array key "hotspot_offset_x" in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Trying to access array offset on value of type null in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Undefined array key "hotspot_offset_x" in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Warning: Trying to access array offset on value of type null in /www/wwwroot/pyrolysismachine.com/wp-content/plugins/elementor-pro/modules/hotspot/widgets/hotspot.php on line 1060

Fully Automatic Pyrolysis Plant

- Feeding size shall be 5-8mm rubber granule, tyre shall be shredded and steel wire will be removed.

- Processong capacity 35-40T/D tyre, 30T/D plastic.

- Fully continuous feeding and discharging in 24hours.

- From feeding to discharging, the whole press is sealed, operation environment is clean.